From Pioneering Trails to Cutting-Edge Solutions: A Journey Through Recombinant Protein Production and Innovations

Recombinant proteins serve as indispensable tools across diverse domains within the life science industry, spanning academic research, diagnostic applications, and the biopharmaceutical sector. With a multitude of applications, their significance is undeniable. This article embarks on a journey that begins with a concise historical overview of recombinant protein expression. As we delve into the narrative, we uncover the pivotal challenges that marked this path, the innovative breakthroughs that have shaped the contemporary landscape of biomanufacturing. Our experts engage in insightful discussions, addressing specific technical hurdles frequently encountered during protein expression campaigns. Additionally, they highlight the ingenious strategies employed to overcome these challenges. We illuminate how our holistic platform is meticulously structured to amplify the likelihood of success, emphasizing our characterization-driven methodology that steers custom projects towards fruition. Lastly, we provide a glimpse into our ongoing 'back-to-lab' special offer, synergizing with the upcoming academic season.

Evolution of Recombinant Protein Expression: From Inception to Cutting-Edge Engineering

The journey of recombinant protein expression has been a remarkable tale of scientific innovation and ingenuity, shaping the way we harness proteins for diverse applications. Emerging in the 1970s, the field has rapidly advanced, punctuated by critical milestones that have paved the way for the engineering capabilities we possess today.

Initially, bacterial systems, particularly E. coli, played a pivotal role. The 1980s witnessed the development of plasmid vectors and the concept of gene fusion, enabling the expression of foreign proteins in bacterial hosts. The advent of high-yield protein purification methods and the use of affinity tags further streamlined protein production. These breakthroughs laid the foundation for today's efficient bacterial expression platforms, enabling rapid production and optimization of proteins for research, diagnostics, and industrial applications.

In parallel, eukaryotic expression systems, such as HEK (human embryonic kidney) and CHO (Chinese hamster ovary) cells, emerged as powerful tools. The 1990s marked significant progress with the improvement of transfection techniques and the development of stable cell lines. This led to the production of complex and post-translationally modified proteins, crucial for therapeutic applications. The integration of bioreactor technologies and advanced cell engineering further propelled eukaryotic systems into the forefront of protein expression, enabling the production of high-value biotherapeutics with enhanced yields and quality.

Today, we find ourselves equipped with an arsenal of innovative tools and techniques, ranging from advanced genetic engineering to precise control of culture conditions. These achievements, stemming from both bacterial and eukaryotic advancements, have collectively empowered researchers and industries to engineer proteins with unprecedented precision and efficiency, ushering in a new era of scientific exploration and therapeutic development.

Unveiling the Frontier: Navigating Challenges and Unleashing Opportunities in Recombinant Protein Expression

Discover in the next sections insights of our expert Patrice Filée, PhD, Protein Engineering Expert and Head of Immunobiology Laboratory at CER Groupe and.

While expression of recombinant proteins presents a promising avenue for protein production, it's not without its challenges and issues. For example, while interesting in terms of productivity, one prominent hurdle in E. coli is the formation of inclusion bodies—insoluble protein aggregates that form when proteins are overexpressed. Although inclusion bodies can sometimes be solubilized and refolded, this process is intricate and doesn't always yield functional proteins. Moreover, the host's proteolytic enzymes can degrade the expressed protein before it even reaches its active state, particularly when dealing with proteins that are foreign to E. coli.

Advanced renaturation strategies can sometimes resolve these aggregates and lead to the proper refolding of a high proportion of the inclusion bodies. Nevertheless, challenging proteins could require innovative upstream strategies to directly obtain soluble material properly refolded. For example, some recombinant proteins may require specific assistance for proper folding in the cytoplasmic and periplasmic spaces or the culture media. Achieving this involves exploiting E. coli's chaperone/secretion machinery, which may need to be engineered for optimal functionality. However, this machinery doesn't always efficiently folds and/or transport heterologous proteins, leading to incomplete translocation or degradation.

Chaperone proteins play a pivotal role in ensuring proper protein folding within E. coli, serving as both facilitators and potential obstacles. Indeed, while these chaperones are essential for preventing aggregation and promoting accurate folding, they can also sequester the recombinant protein, limiting its availability for downstream applications. To overcome this challenge, researchers have pursued a dual-pronged strategy. Firstly, they explore the co-expression of specific chaperone proteins alongside the target protein within E. coli. This approach aims to provide the necessary assistance for correct folding, leveraging the chaperones' expertise to enhance the yield of functional proteins. Additionally, researchers have tapped into the potential of chemical chaperones, which can be introduced into the culture medium. These chemical chaperones act in synergy with the endogenous cellular machinery, aiding in protein folding without overwhelming the host's natural systems. This collaborative effort between the co-expressed chaperones and the chemical chaperones present in the medium optimizes the folding landscape for the produced proteins.

Codon usage discrepancies also pose challenges. If the codon usage in the target gene differs significantly from E. coli's natural preference, translation efficiency can be compromised, resulting in low protein expression levels. This issue is exacerbated by the potential formation of secondary structures like hairpins in the mRNA, which can hinder ribosome binding and protein translation. These challenges are particularly problematic for complex proteins or those with a high GC content.

In navigating these challenges, researchers have the opportunity to leverage protein engineering and bacterial engineering. Protein engineering techniques can be employed to optimize the target protein for expression in E. coli, improving solubility, stability, and compatibility with the host's translational machinery. On the other hand, bacterial engineering involves modifying the host E. coli strain to enhance its protein production capabilities, addressing issues like protease activity, codon usage biases, and mRNA secondary structure formation.

By strategically combining gene optimization, protein engineering, bacterial engineering, and the use of chaperones, researchers can enhance protein solubility, prevent degradation, and improve overall expression yields. These approaches underscore the importance of a multidisciplinary approach in successfully producing functional recombinant proteins in E. coli.

Advancing Recombinant Protein Production: Triumphs and Strides in HEK293 and CHO Systems

In parallel of advances described for E. coli use for protein production, the landscape of recombinant protein production in mammalian cells, particularly in the context of HEK293 (human embryonic kidney) and CHO (Chinese hamster ovary) systems, has also experienced a remarkable transformation. A journey marked by both challenges and achievements has propelled these systems to the forefront of bioengineering, making protein production more accessible and efficient than ever before.

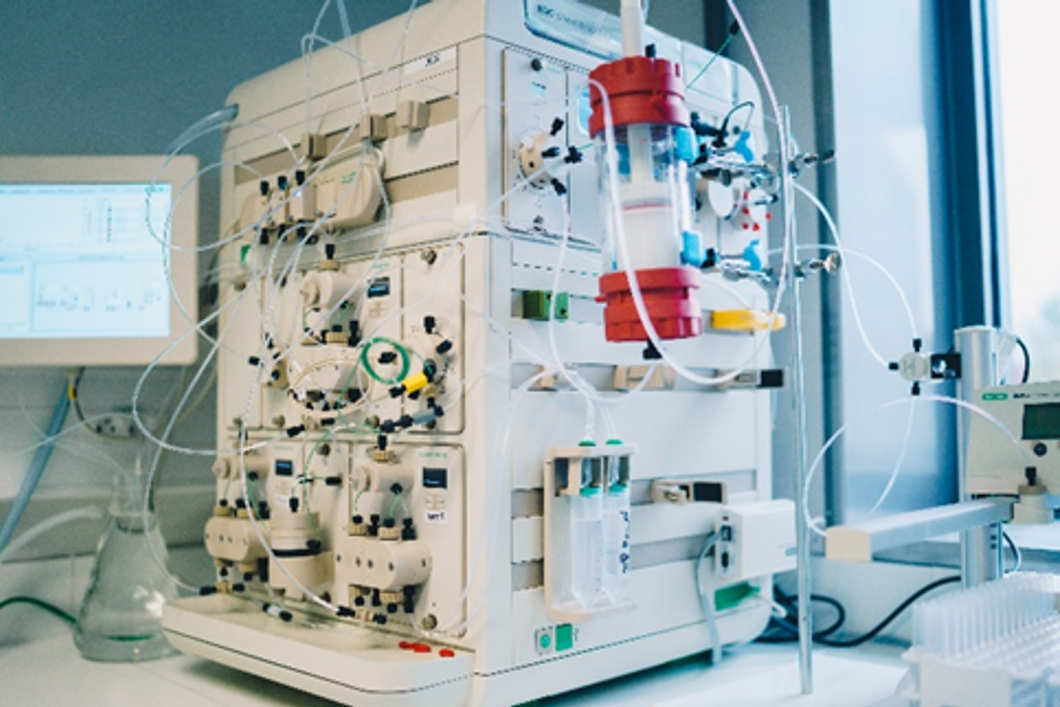

Conquering obstacles has been a pivotal theme in this evolution. Early challenges, such as scalability and cost-effectiveness, once hindered the potential of mammalian cell-based production. Yet, through concerted efforts, researchers have innovated scalable cultivation methods, optimizing growth media and refining bioreactor technologies. This groundbreaking progress has facilitated larger-scale production, making mammalian systems economically viable and opening doors to wider applications.

Another cornerstone has been the quest for high protein yields coupled with stability. This endeavor led to significant strides in gene expression optimization. Techniques like codon optimization, promoter selection, and signal peptide engineering have elevated protein expression levels in HEK293 and CHO cells. Moreover, the development of high-yielding stable cell lines has established a foundation for consistent and reliable protein production. More recently, process optimization through digitalization and advanced modelling strategies (e.g. digital twin) further enabled to go beyond the limits of biomanufacturing, through process optimization acceleration and thorough development costs reduction.

Milestones have been achieved on this journey. The glycoengineering breakthrough in CHO cells stands as a pivotal achievement, enabling the production of glycosylated proteins with human-like glycan structures. This advancement significantly impacted biopharmaceutical development by enhancing the efficacy and safety profiles of therapeutic proteins. The transition from adherent to suspension cultures, accompanied by ingenious high-density culture strategies, has revolutionized scalability, reducing production times and enhancing efficiency. Integration of advanced bioprocess monitoring and control technologies further elevates precision, ensuring the reproducibility of high-quality protein production.

In essence, the story of recombinant protein production in HEK293 and CHO cells epitomizes resilience and innovation. It showcases how challenges can be overcome through persistent efforts, transforming limitations into opportunities. As these systems continue to evolve, they empower researchers to unravel scientific mysteries and drive therapeutic advancements with greater precision and impact.

CER Groupe: Crafting Success with Agility and Expertise in Recombinant Protein Production

The CER Groupe experts capitalize on their proficiency in protein and cell engineering to pave the way for enhanced protein solubility, stability, and optimal folding. We recognize that each protein project is unique, demanding tailored strategies. Our molecular, physicochemical, and biological characterization techniques serve as a compass, steering the optimization process.

Discover the forefront of recombinant protein production with CER Groupe's innovative services! Our expertise in protein biochemistry and characterization empowers a comprehensive approach to optimize protein expression in E. coli and their use in various applications that will be considered during strategy establishment (always begin with the end in mind). The path to successful production can be a labyrinthine journey, marked by challenges like inclusion body formation, proteolytic vulnerability, codon usage disparities, … But with CER Groupe, these challenges become opportunities for breakthroughs. Our team's profound understanding of E. coli and mammalian cells biology intricacies transforms this journey into an informed decision-making process, where we leverage our expertise to guide you through the challenge of protein expression.

At CER Groupe, we don't just produce proteins — we craft solutions.

Contact us today to discuss your project and start a transformative collaboration !

Contact : info@cergroupe.be

Discover our solutions at www.cergroupe.be.

Other news